Contact Robey's Powerkleen at 859-484-7337

Tennant T600e Walk-Behind Floor Scrubber

$325.00

Duration

Quantity

Frequently Asked Questions

What width floor scrubber should I choose?

A 26-inch machine can fit through standard doorways, making it a versatile option for most spaces.

A 32-inch machine, however, is too wide to pass through standard doorways, so it's better suited for open areas.

What are pads & pad drivers?

A pad on a floor scrubber is a replaceable, disc-shaped cleaning attachment that makes direct contact with the floor to perform tasks such as scrubbing, buffing, or polishing. In contrast, a pad driver is the component that securely holds the pad in place, allowing it to rotate and effectively clean the floor. Essentially, the pad driver serves as the connection between the cleaning pad and the machine.

Key Differences Between Pads and Pad Drivers:

Function:

Pads vary in texture and abrasiveness based on the cleaning task, whether it's scrubbing tough dirt, polishing, or stripping old floor finishes.

Attachment:

The pad driver features a gripping surface (often with Velcro-like material) to keep the pad securely attached to the scrubber during operation.

Types of Pads:

Pads come in different colors to indicate their purpose—for example, blue for general scrubbing, white for polishing, and black for stripping.

For this Product - A red buffing pad is slightly more abrasive and designed for general cleaning tasks, such as removing light scuffs and stains. In contrast, a white buffing pad is the softest option, primarily used for polishing and achieving a high-gloss finish on floors. Among all pad colors, white is the least aggressive.

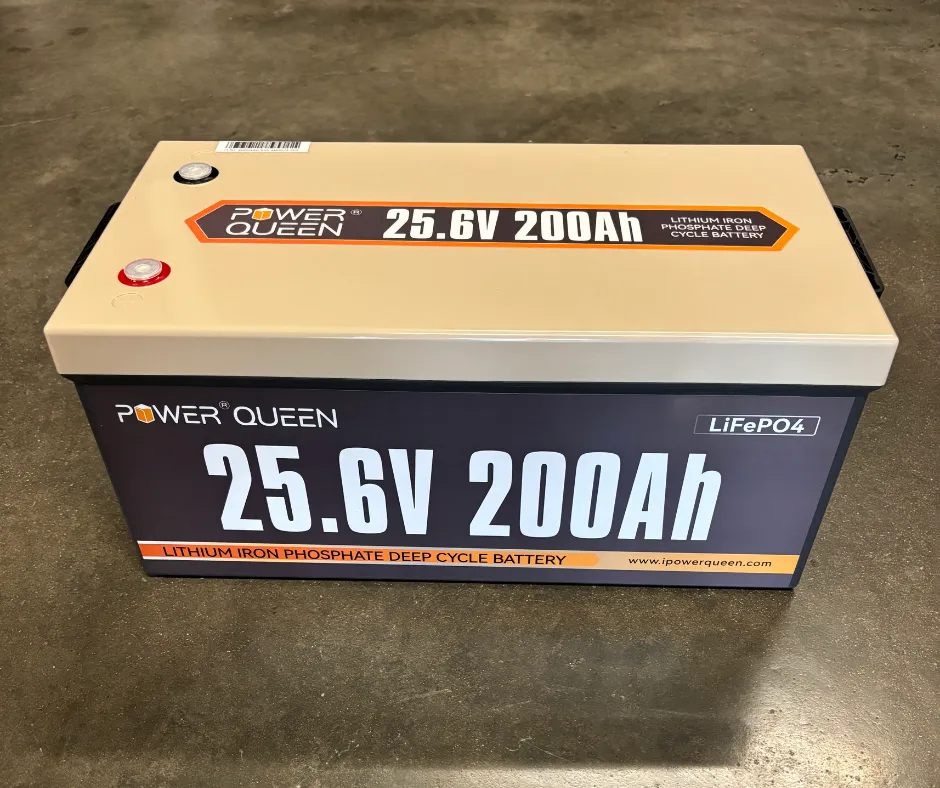

What battery should I choose?

The primary difference between a small and large lithium battery pack on a floor scrubber is its capacity, or the amount of power it can store. This directly affects how long the scrubber can operate on a single charge—a larger battery pack provides longer runtime before needing a recharge.

Key Factors to Consider

Cleaning Area:

Larger spaces generally require a bigger battery pack to support extended cleaning sessions.

Work Intensity:

If scrubbing heavy dirt or rough surfaces, a larger battery pack may be more efficient.

Charging Time:

While bigger batteries may take longer to recharge, their extended runtime often makes up for this.

What brush is good for my facility?

A poly blend brush bristle on a floor scrubber is primarily made from polypropylene, which is stiffer and more abrasive than a nylon blend brush bristle. Nylon bristles are more flexible and gentler, making them better suited for softer floors, while polypropylene is ideal for hard surfaces like concrete. Both materials are synthetic and can be blended with other fibers to enhance specific cleaning properties.

Key Differences Between Poly Blend and Nylon Blend Bristles

Poly Blend Bristles:

Stiffness: Rigid and abrasive, ideal for heavy-duty scrubbing on hard floors.

Durability: More economical but may wear out faster than nylon.

Chemical Resistance: Highly resistant to chemicals, fungus, and bacteria.

Nylon Blend Bristles:

Flexibility: Softer and more flexible, making it suitable for delicate floor surfaces.

Durability: Longer-lasting than polypropylene, with better resistance to heat and chemicals.

Cleaning Power: Still provides effective scrubbing for general cleaning tasks.

Why Customers Choose Us

This company is super responsive and the service is great! Any questions we have had have been answered with detail. Highly recommend! We are a car service business located in Nicholasville Ky and high traffic can mean big messes but it’s never an issue with this team to support your cleaning needs!

This is our first floor cleaner purchased for a 30,000 square foot building. We should have done this sooner. It came to us just as it was described. We are a company that focuses on customer service, it is refreshing to work with a company like Robey’s that treats us like we treat our customers. They did a video meeting before the purchase to help us choose which machine, and they have made several follow-up calls since it was delivered. There is no reason to purchase new. Great company to work with, we will be purchasing from them again.

This company is super responsive and the service is great! Any questions we have had have been answered with detail. Highly recommend!

We are enjoying and excited about our floor cleaner. We use it few times per week. Everyone from company I talked to was helpful and easy to work with on all aspects of process. Thank you again for a great product.

Industrial Cleaning Knowledge

Tennant T500e vs T5e: What’s the Difference and Which Floor Scrubber Should You Buy?

Tennant T500e vs T5e explained. Learn the key differences, upgrades, and which walk-behind floor scrubber is the better choice for commercial and industrial cleaning. ...more

Shopping Guide ,Blog articles Effortless Floor Cleaning Solutions Janitorial Equipment Buying Guides Green Cleaning Trends Maximizing Cleaning Efficiency Affordable Cleaning Solutions Floor Care Essentials &The Future of Cleaning Tech

February 09, 2026•3 min read

How to Choose the Right Floor Scrubber or Sweeper

A practical guide to choosing the right floor scrubber or sweeper for commercial, industrial, and agricultural facilities. Learn what to consider before buying and avoid costly mistakes. ...more

Blog articles ,Effortless Floor Cleaning Solutions Green Cleaning Trends Maximizing Cleaning Efficiency Affordable Cleaning Solutions Floor Care Essentials Pro Tips for Industrial Cleaning Maintaining Your Equipment The Future of Cleaning Tech &Success Stories in Clean Spaces

January 10, 2026•3 min read

Tennant T7 Floor Scrubber Demo at Indianapolis Public Transportation

Watch the Tennant T7 floor scrubber in action at an Indianapolis public transportation facility. Built for heavy foot traffic and industrial concrete floors, this machine delivers reliable, no-nonsens... ...more

Shopping Guide ,Blog articles Effortless Floor Cleaning Solutions Janitorial Equipment Buying Guides Green Cleaning Trends Maximizing Cleaning Efficiency Affordable Cleaning Solutions Floor Care Essentials &Pro Tips for Industrial Cleaning

December 15, 2025•2 min read